CNC Machining

Precision parts with tight tolerances.

Reduce mold costs and validate part designs with a low-cost prototype tool.

Precision parts with tight tolerances.

Fast prototyping with various materials.

Custom metal parts and enclosures.

Polishing, painting, anodizing, and more.

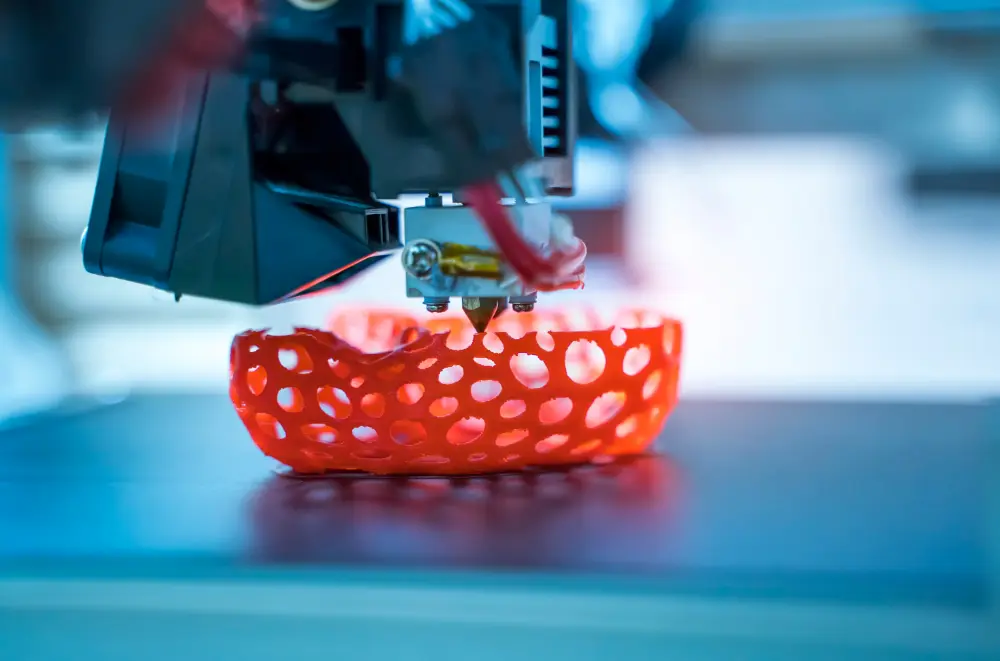

Reliable one-stop manufacturing partner for B2B clients—offering CNC machining, injection molding, 3D printing, and more from prototyping to production.

Extensive multi-material machining expertise

Short lead times with consistent quality

Engineering team with 8+ years of experience on average

ISO-standard workflows &professional communication

We help you accelerate development with reliable, production-quality prototypes.

To start, simply select a manufacturing process and upload a 3D CAD file.

Within hours, we'll provide your DFM analysis and real-time pricing.

Once you confirm your quote and order, we’ll begin manufacturing.

Find answers to your most pressing questions about our rapid prototyping services.

Prototyping is the process of creating a preliminary model of a product to test its design, functionality, and usability before mass production. It’s essential for identifying design flaws, improving product performance, and ensuring the final product meets all requirements without costly production errors.

The time required to create a prototype depends on its complexity and the materials involved. Simple prototypes may take only a few days, while more intricate designs or larger models might take a week or more. We work with you to set a realistic timeline for your project.

We offer a wide range of materials for prototyping, including plastics (ABS, PMMA, PC), metals (aluminum, stainless steel, titanium), and composites (carbon fiber, fiberglass). The choice of material depends on the prototype’s intended function, durability, and aesthetic requirements.

Yes, we specialize in creating prototypes for both simple and complex designs. Our advanced manufacturing technologies, including CNC machining and 3D printing, allow us to handle intricate geometries and detailed features, ensuring your design is faithfully represented.

To request a quote, simply share your design files and project details (material choice, size, complexity, and quantity). Our team will review your requirements and provide you with a customized quote, along with a timeline for completion.

Yes, we can make revisions to your prototype based on feedback or testing results. If there are any design changes or adjustments needed, we work with you to refine the prototype before finalizing it for production.