Consumer Electronics

Accelerate innovation to bring the consumer technology products of the future to market now.

With over a decade of experience, ProtoCraft specializes in delivering high-precision prototype solutions tailored to your needs. Our expertise in rapid prototyping, CNC machining, and 3D printing ensures you receive quality results on time, every time.

Our models start out with the correct gauge of 4′ 8 1/2″ and scale AAR wheel profile and continue throughout the model to create an accurately scaled replica of the prototype.

Learn More >>

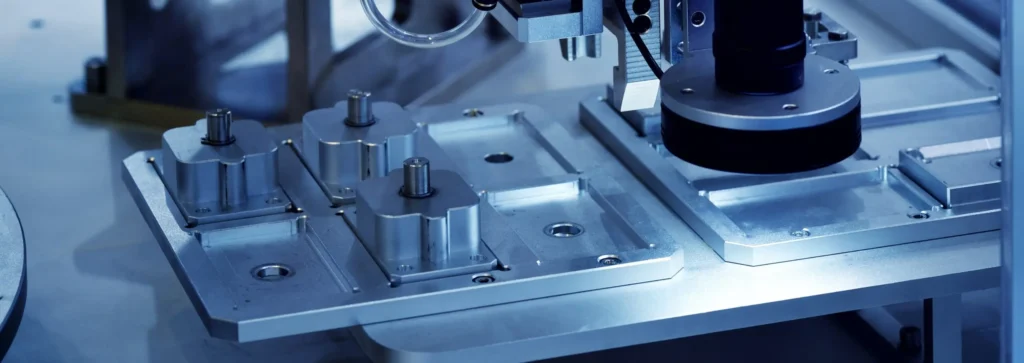

CNC excellence delivers high-precision machining, ensuring complex components meet the tightest tolerances with exceptional accuracy, reliability, and efficiency.

Learn More >>

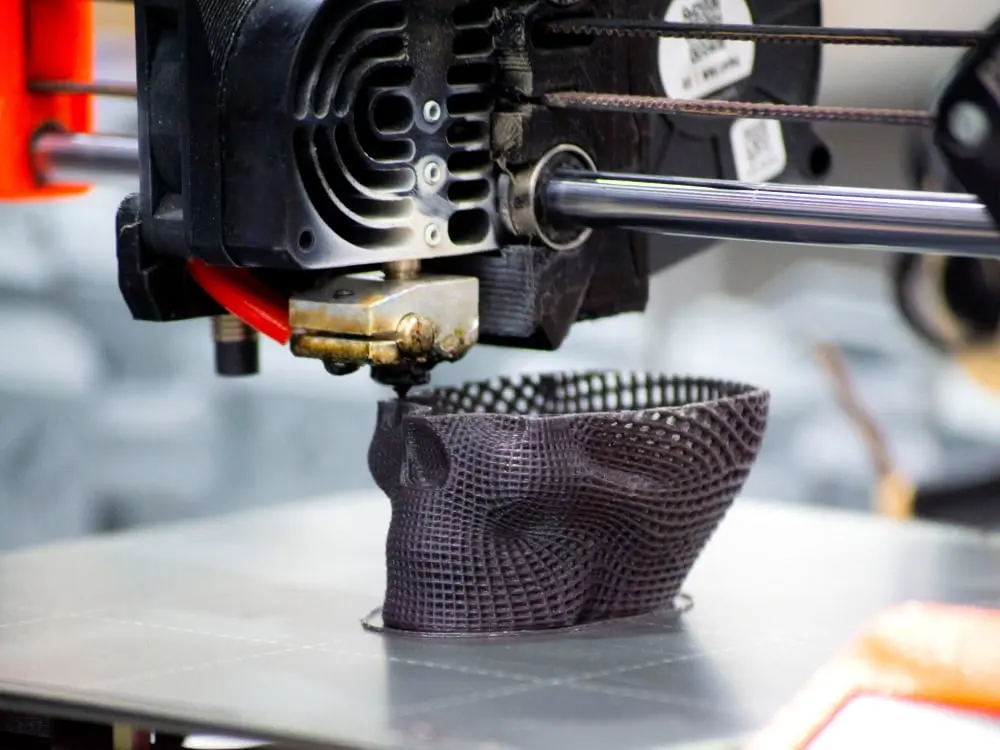

Choose from different additive manufacturing technologies for cost-effective prototyping and highly accurate, repeatable production parts.

Learn More >>

ProtoCraft Manufacturing Co., Ltd. is a leading provider of one-stop product development solutions, offering comprehensive services from industrial product design to mass production.

Founded in 2021, ProtoCraft Manufacturing Co., Ltd. provides prototyping, CNC machining, and 3D printing solutions, helping businesses turn ideas into reality with advanced technologies and a focus on quality.

High-precision prototypes tailored to your needs.

Fast delivery without compromising on quality.

Expert support throughout your prototyping journey.

One-stop product development services offering CNC machining, 3D printing, vacuum casting, and sheet metal fabrication for aerospace, automotive, medical, and more.

Employ over 100 skilled staff

Covering an area of 5000+ square meters

Equipped with more than 60 advanced machines

10+ years in high-speed, multi-axis CNC machining

To start, simply select a manufacturing process and upload a 3D CAD file.

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Once you confirm your quote and order, we’ll begin manufacturing.

Accelerate innovation to bring the consumer technology products of the future to market now.

ProtoCraft creates precision props, models, and artworks for studios, and artists, brands.

Rapid prototyping and ramp-up production for traditional, electric, and autonomous vehicles.

From prototyping to testing to final production, we speed up your time to market.

Rapid prototyping lets companies quickly test and validate designs before mass production, ensuring success in a competitive market.

“ProtoCraft exceeded our expectations with their attention to detail and fast turnaround. Our prototypes were flawless and ready for presentation ahead of schedule.”

“Working with ProtoCraft was a great experience. Their team was responsive, professional, and delivered high-quality parts that matched our designs perfectly.”

“ProtoCraft’s craftsmanship and reliability made a real difference to our project. Their team understood our needs and delivered exceptional results every step of the way.”

From product development to industrial 3D manufacturing, we can help you scale your business.

Prototyping involves creating an early sample or model of a product to test and validate its design, functionality, and performance before mass production. It's crucial because it helps identify design flaws, ensures feasibility, and saves time and cost in the long run. By testing a prototype, you can make necessary adjustments before finalizing the product for manufacturing.

Our industrial 3D printing, CNC machining, sheet metal fabrication, and injection molding services provide parts made directly from the customer’s 3D CAD model, reducing the likelihood of errors. Proprietary software automates toolpath generation to decrease manufacturing times and reduce costs.

We offer a wide range of materials, including plastics (ABS, PMMA, PC, etc.), metals (aluminum, stainless steel, titanium), and specialized materials like carbon fiber composites and resin. The choice of material depends on the functionality and requirements of your prototype.

You can easily request a quote by contacting us directly through our website. Simply provide details about your project, including design specifications, materials, and quantities. Our team will get back to you with a detailed estimate and timeline.